Good Tobacco Dip: A Complete Industry Guide to Understanding Manufacturing, Quality, and Market Demand

Good Tobacco Dip: A Complete Industry Guide to Understanding Manufacturing, Quality, and Market Demand

Introduction: What Makes a “Good Tobacco Dip”?

Tobacco dip—commonly known as moist snuff—is a staple within the smokeless tobacco industry. But what defines a truly good tobacco dip product? Is it the robust flavor, the satisfying texture, the consistent nicotine delivery, or the overall quality that drives consumer loyalty and market success? This guide explores the essential components of tobacco dip, why quality is paramount for consumer satisfaction and health considerations, and how market demand shapes production and innovation.

The Tobacco Dip Manufacturing Process

Producing premium tobacco dip demands careful raw material selection and precise manufacturing techniques to ensure product consistency and appeal. The key steps include:

1. Raw Tobacco Selection

High-grade tobacco leaves are chosen based on strain, chemical profile, moisture content, and purity. These factors directly influence the flavor, aroma, and nicotine strength of the final product.

2. Curing and Fermentation

Tobacco undergoes curing via air-curing, fire-curing, or flue-curing methods. Each imparts distinct flavor nuances. Subsequent fermentation deepens flavor complexity and reduces harshness, enhancing smoothness and consumer appeal.

3. Grinding and Blending

Cured tobacco leaves are ground uniformly to produce a fine, manageable texture. Blending different batches or leaf types enables manufacturers to tailor flavor intensity and nicotine levels.

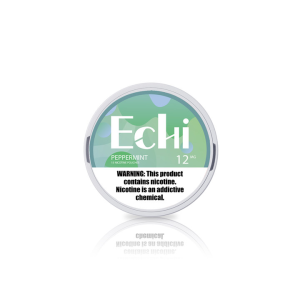

4. Flavoring Additives

Flavor innovation plays a crucial role in market differentiation. Popular flavor profiles include mint, wintergreen, cinnamon, and assorted fruit blends, alongside unflavored “natural” options for traditional users. Flavor extracts are carefully infused to balance taste and freshness.

5. Packaging

Final products are packaged to maintain freshness and ensure consumer convenience. Leading manufacturers, including Snuff Factory, increasingly emphasize eco-friendly packaging solutions responding to sustainability trends.

What Differentiates Good Dip Products from Inferior Ones?

Key Quality Markers:

-

Consistent Taste: Whether bold or mild, the flavor should be steady throughout the product’s lifespan.

-

Optimal Moisture: Proper moisture enhances ease of use and flavor longevity without becoming messy.

-

Texture: A smooth, evenly blended product allows easy pinching and placement under the lip.

-

Nicotine Strength: Availability of varied nicotine levels caters to different consumer preferences, from novices to experienced users.

Common Pitfalls in Low-Quality Dip:

Subpar dips often suffer from uneven grinding, poor-quality tobacco, artificial or overpowering flavoring, and inconsistent nicotine delivery. These factors harm brand reputation and reduce consumer loyalty.

Pros and Cons: Traditional vs. Innovative Tobacco Dip Formulations

Traditional Dip:

-

Pros: Established market demand and authentic user experience.

-

Cons: Limited appeal among younger demographics; fewer flavor varieties.

Innovative Dip (e.g., flavored, reduced-nicotine, nicotine-free):

-

Pros: Attracts broader audiences, including health-conscious and novice users.

-

Cons: Increased R&D and production costs.

Modern manufacturers are exploring reduced-risk formulations to meet rising consumer expectations for healthier alternatives without compromising satisfaction.

Market Application Scenarios and Audience Demand

Consumer Segments:

-

Traditional Users: Loyal smokeless tobacco consumers.

-

Younger Generations (Millennials & Gen Z): Drawn to flavor innovation and modern packaging.

-

Health-Conscious Niches: Interested in reduced-nicotine or nicotine-free options.

Geographic Demand:

High consumption regions include North America, Scandinavia, and emerging markets in Asia. Understanding regional preferences is critical for product development and marketing strategies.

Frequently Asked Questions

Q1: What is the shelf life of high-quality tobacco dip?

Properly stored in airtight containers at stable temperatures, dip typically retains freshness for 6 to 12 months.

Q2: Are premium tobacco dip options available?

Yes. Premium dips often feature select tobaccos, refined fermentation, and superior flavor blends.

Q3: How does dip differ from snuff or chewing tobacco?

Dip contains higher moisture than dry snuff and is placed between the lip and gum without chewing, unlike chewing tobacco which requires mastication.

Q4: Where can brands source premium tobacco dip?

Established manufacturers like Snuff Factory offer bulk formulations and customized product solutions tailored to brand needs.

Conclusion: Navigating Your Tobacco Dip Journey

A “good tobacco dip” blends quality raw materials, precise manufacturing, and consumer-driven innovation. For B2B buyers, wholesalers, and new brands, partnering with trusted suppliers is crucial. Companies like Snuff Factory provide reliable access to high-grade tobacco dip products and industry expertise, helping you deliver satisfaction across your customer base.

Make informed choices—your product’s success depends on it.

Leave a Reply

Want to join the discussion?Feel free to contribute!