High-Mg Nicotine Pouches: A Strategic Guide for B2B Buyers and Brands

Nicotine pouches have emerged as a key category within the modern nicotine market, offering a smokeless, discreet alternative to traditional tobacco. Among these, high milligram (mg) nicotine pouches have carved out a specialized niche—designed for experienced users seeking stronger options or transitioning away from combustible products. For manufacturers, distributors, and brand owners, understanding how these products are developed, positioned, and regulated is essential for successful market entry and sustained growth.

This guide outlines the formulation processes, key advantages and trade-offs, and supplier considerations specific to high-mg nicotine pouches, equipping B2B stakeholders with the clarity needed to scale confidently in this high-performance product segment.

Defining High-Mg Nicotine Pouches

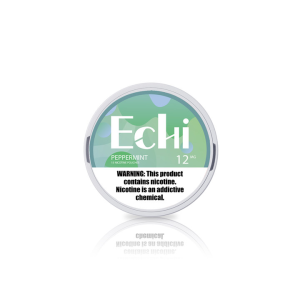

Unlike entry-level products that contain 3–6 mg of nicotine per pouch, high-mg variants typically range from 8 mg to 20 mg. This higher dosage appeals to users with elevated tolerance levels, including former smokers or those previously using stronger smokeless tobacco products.

The rising demand for high-potency pouches stems from their ability to replicate the satisfaction of traditional nicotine delivery methods—without combustion, odor, or tobacco content.

Inside the Manufacturing Process

The development of high-mg nicotine pouches requires meticulous formulation and a production environment capable of ensuring consistency, safety, and regulatory compliance. Here’s a breakdown of the core stages:

Nicotine Sourcing and Preparation

Nicotine used in high-strength pouches typically comes from two sources:

-

Naturally extracted nicotine, derived from tobacco leaves using liquid extraction and purification.

-

Synthetic nicotine, which replicates the chemical structure without any tobacco-derived components. This option is increasingly favored for tobacco-free labeling and regulatory flexibility.

Both options require working with an experienced nicotine manufacturer who can ensure purity and dosage accuracy at scale.

Base Formula and Delivery System

The pouch filler—typically composed of plant fibers, microcrystalline cellulose, or gum bases—serves as the medium for nicotine and flavor dispersion. In high-mg products, the formulation must strike a balance between potency and comfort, avoiding harshness while ensuring fast absorption.

Key considerations at this stage include:

-

Nicotine loading efficiency

-

pH control to optimize absorption

-

Sensory agents to reduce irritation

Flavor Development

Flavoring is critical to product acceptance. Mint, menthol, and citrus remain dominant, though brands exploring unique blends often stand out. For high-mg pouches, flavor must complement—not compete with—the nicotine hit. This requires more nuanced formulation than with low-dose products.

Packaging and Stability Testing

Due to higher active content, high-mg pouches demand packaging solutions that protect against oxidation and preserve moisture. Most are sealed in airtight, child-resistant cans with bold graphics signaling strength and usage intent.

Quality control tests typically include:

-

Nicotine content validation

-

Leak and stability testing

-

User sensory testing

These checks are especially important when partnering with a nicotine factory for high-volume production.

Advantages and Limitations

Pros:

-

Meets the needs of experienced users seeking strong, fast-acting alternatives

-

Differentiates your product portfolio in a saturated mid-strength market

-

Enhances brand value in competitive retail environments, especially in mature markets

Cons:

-

Narrower user appeal, often unsuitable for first-time users

-

Higher formulation risk, requiring experienced manufacturing partners to ensure comfort and consistency

-

Regulatory constraints, as some jurisdictions cap permissible nicotine levels

Close collaboration with a compliant liquid nicotine wholesaler or production partner is crucial to navigating these complexities.

Key Use Cases and Market Demand

High-mg pouches are well-suited for:

-

Smokers switching to tobacco-free formats who seek comparable satisfaction levels

-

Long-time pouch users desiring more intense options

-

Markets with regulated tobacco but open pouch sales, including the U.S., Scandinavia, and select EU countries

Regional differences in regulation and consumer expectations make market-specific formulation and positioning essential.

FAQs: High-Mg Nicotine Pouches in B2B Context

Are high-mg nicotine pouches safe?

When formulated correctly and used as directed, they provide a safer alternative to combustible tobacco. Sourcing from a certified nicotine patch manufacturer or pouch producer ensures product integrity.

How do they compare to cigarettes?

While nicotine delivery may feel comparable in intensity, pouches eliminate combustion, secondhand smoke, and tobacco leaf content—making them more acceptable in health-conscious markets.

What should B2B buyers look for in a supplier?

Stability, production capacity, GMP or ISO certifications, transparent test reporting, and clear communication channels. Platforms like Snuff Factory provide direct access to tested formulations and reliable wholesale supply.

Are high-mg options legal everywhere?

No. Several countries restrict nicotine strength. B2B buyers should confirm compliance regionally and partner with a well-informed producer like Snuff Factory to ensure market readiness.

Finding the Right Partner

Success in the high-mg segment depends on more than just product development. Supplier relationships directly influence speed-to-market, formulation accuracy, and regulatory compliance. Whether you are launching a house brand or scaling OEM production, selecting an experienced manufacturer ensures your high-nicotine products meet performance, safety, and consumer demand.

Snuff Factory supports global clients with white-label and OEM solutions tailored for high-mg formats. Their end-to-end services—from R&D to regulatory packaging—streamline the transition from concept to shelf.

Final Thoughts

High-mg nicotine pouches offer a compelling option for experienced users and a strategic opportunity for forward-looking nicotine brands. With growing consumer interest and evolving regulations, the timing to expand into this segment is ideal—but requires precision at every step.

From formulation to packaging to supplier selection, success comes from working with the right partners and maintaining a clear focus on both compliance and consumer satisfaction.

If you’re ready to explore high-mg pouch production, connect with Snuff Factory to access custom manufacturing and wholesale solutions built for scale.

Leave a Reply

Want to join the discussion?Feel free to contribute!