A Comprehensive Operation Guide for Nicotine Product Businesses: From Industry Trends to Reliable Manufacturing Partners

Entering the nicotine product market is a complex endeavor requiring careful planning and execution. Entrepreneurs and businesses face numerous challenges, including navigating regulatory frameworks, sourcing high-quality raw materials, understanding intricate production processes, and distinguishing themselves in an increasingly competitive marketplace. Success hinges on making informed decisions at every stage, particularly when selecting a trustworthy nicotine bag manufacturer to ensure consistent product quality and compliance.

Industry Background and Trends

The nicotine product industry has witnessed remarkable evolution over recent years. As consumer awareness around health risks associated with traditional tobacco products increases, there has been a marked shift toward safer, smokeless alternatives such as white label nicotine bags and nicotine gums. This transition is fueled by technological advancements in product formulation and manufacturing, alongside regulatory pressures encouraging reduced-risk nicotine consumption.

Today’s market demands innovative products that balance safety, convenience, and flavor, creating fresh opportunities for businesses that understand these emerging preferences. Staying abreast of these nicotine manufacturing trends is crucial for long-term success.

Production Processes Involved in Nicotine Manufacturing

Manufacturing nicotine products involves a series of precise steps tailored to the specific product format. For example, the nicotine bag manufacturing process typically includes:

-

Sourcing Quality Raw Materials: Procuring pharmaceutical-grade nicotine and food-safe pouch materials to ensure product safety.

-

Blending: Carefully combining nicotine with flavorings and filler bases to create consistent mixtures.

-

Filling Pouches: Using automated machinery to fill each pouch with the exact measured amount of nicotine blend.

-

Packaging: Sealing and packaging products in moisture-resistant containers to preserve freshness and extend shelf life.

Understanding this process helps buyers evaluate manufacturers’ capabilities and quality assurance measures, critical for maintaining regulatory compliance and consumer satisfaction.

Understanding the Landscape – Brands, Origins, and Technology

The nicotine pouch and gum market is populated with diverse brands, each differentiated by production origin, technology, and market positioning. Brands manufactured in regions with advanced regulatory oversight, such as Scandinavia and North America, often command premium pricing due to rigorous quality controls and technological innovation.

Technological advancements include the use of synthetic nicotine to avoid tobacco derivatives, innovative pouch materials that enhance nicotine delivery and flavor retention, and eco-friendly packaging solutions.

Recognizing these differences allows businesses to align their product strategy with the right manufacturing partners and market segments.

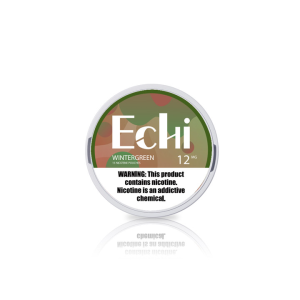

How to Choose a Reliable Supplier: Echi Nicotine Bag Manufacturer

Selecting the right supplier is a foundational step in building a successful nicotine product business. A reputable supplier not only guarantees consistent product quality but also supports your growth through reliable supply chains and regulatory expertise.

When evaluating potential nicotine bag manufacturers, consider:

-

Brand Reputation: Look for manufacturers with proven track records and positive industry reviews.

-

Technological Capabilities: Choose partners employing cutting-edge manufacturing technology for superior product consistency.

-

Skilled Workforce: Ensure the supplier has trained personnel to manage production complexities and quality assurance.

-

Raw Material Sourcing: Verify that raw materials meet stringent safety and purity standards.

-

Production Capacity: Confirm that the supplier can scale production in line with your business growth.

One such trusted partner is Snuff Factory, renowned for its comprehensive nicotine manufacturing solutions including nicotine bag manufacturing and nicotine gum manufacturing services. Their expertise supports businesses in launching and scaling quality nicotine products efficiently.

Concluding Remarks and Final Suggestions

Launching a nicotine product business demands strategic foresight, industry knowledge, and dependable partnerships. By staying informed about current industry trends, prioritizing quality, and aligning with a reliable manufacturer like Snuff Factory, businesses can overcome market entry barriers and capitalize on growth opportunities.

To ensure your venture’s success, begin by consulting experts in nicotine manufacturing and explore tailored solutions such as white label nicotine bags to accelerate your time-to-market with confidence.

Explore further and connect with leading manufacturers today:

Leave a Reply

Want to join the discussion?Feel free to contribute!