Strong snus is making a big splash in the world of tobacco that doesn’t need to be smoked. A lot of people want to use it because it has a lot of nicotine.

This product gives a strong nicotine hit to people who want one. There are different strengths of it, such as extra strong snus.

Strong nicotine pouches are a tobacco-free option that health-conscious people like. These pouches give you a similar nicotine high without the tobacco.

The rise of strong snus shows that people’s tastes are changing. People want options that are easy to use and fit in with their busy lives.

As the market grows, more and more people are buying strong snus. Its strength and flexibility are what make it appealing.

What is Strong Snus? Where it came from and how it changed

Strong snus is a type of smokeless tobacco that has a lot of nicotine in it. You put a piece of it under your upper lip to use it. The nicotine gets into the body quickly through the gums.

Snus has a long history that starts in Sweden. People in Scandinavian countries used to enjoy it the most. Over the years, the production process has changed to put more emphasis on safety and quality.

Strong Snus has these important features:

-

Use without smoke, put it under the lip.

-

Tobacco that has been pasteurized to get rid of harmful chemicals.

-

Comes in different flavors and amounts of nicotine.

New ideas have helped strong snus grow and change over time. Techniques have gotten better, giving users more choices. This is part of a larger trend toward nicotine products that aren’t cigarettes.

Strong snus keeps changing to meet the needs of today. It finds a middle ground between old and new needs. As it becomes more popular around the world, its roots are still an important part of who it is.

Different kinds of strong snus: From Strong to Very Strong

There are different kinds of strong snus, each with a different amount of nicotine. These choices are good for people with different tastes and experiences.

Most of the time, the differences are in how much nicotine they have. Standard strong snus gives you a balanced dose of nicotine. It is good for a lot of people who want to have a good time.

But seasoned users like extra strong snus. It has more nicotine, which gives it a strong kick. This variant meets the need for a stronger choice.

Common Types of Strong Snus:

-

Strong Snus: Normal but good.

-

Extra Strong Snus: For a stronger experience.

-

Ultra-Strong Snus: The most nicotine possible.

There is a strong snus for everyone because there are so many different kinds. People can choose based on how much nicotine they want. This availability is one reason why snus is so popular.

There is a perfect type for you, no matter how good or bad you are. This flexibility makes users happier and more satisfied.

Strong Nicotine Pouches: A Way to Get Nicotine Without Tobacco

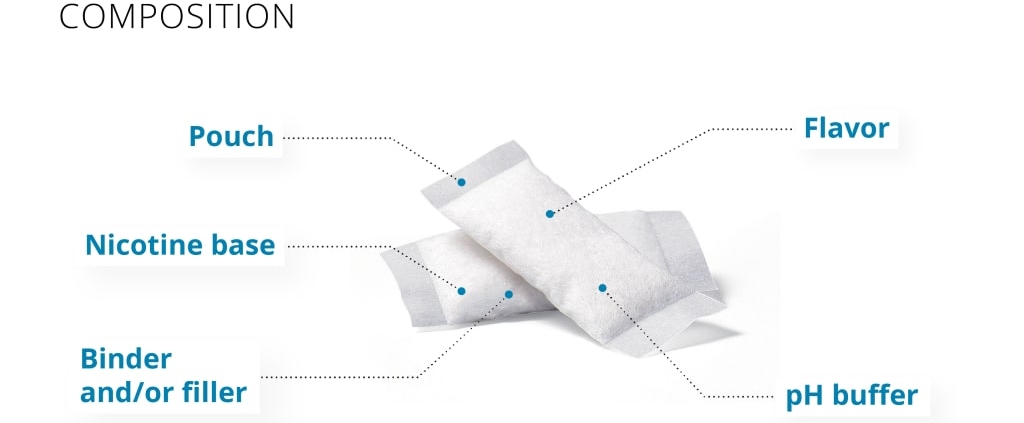

Strong nicotine pouches are a new, tobacco-free option for people who want to use them. These pouches have a lot of nicotine in them, but they don’t have any tobacco. They are for people who want a clean option.

The pouches are small and simple to use. They fit well in the mouth, which is convenient. A lot of people like that there is no smoke and that it is easy to use.

The fact that there are so many flavors is a big draw. There are many choices, from minty to fruity. People can satisfy their nicotine cravings while also enjoying different flavors.

Strong Nicotine Pouches Have These Important Features:

-

No tobacco in the mix

-

Different tastes

-

A lot of nicotine

In today’s market, their versatility and appeal are only getting stronger. This growth shows that people’s tastes in nicotine are changing. More and more people are choosing alternatives like these pouches.

Why is Strong Snus becoming more popular?

In recent years, the demand for strong snus has grown a lot. There are many reasons for this trend, but being discreet is one of the most important. People can use it whenever they want without anyone noticing.

People like strong snus because it gives them a strong nicotine high. People who have used this before often look for this level of strength. It gives you a quick hit of nicotine with less risk to your health than smoking.

People also like the different flavors. There is something for everyone, from regular tobacco to rare blends. This type adds to the sensory experience.

Strong snus also goes well with modern life. It is easy to use, which is good for busy people. Snus is portable and doesn’t make smoke, which is great for city life.

Why It’s So Popular:

-

Use without being noticed

-

Strong nicotine experience

-

A lot of different flavors

-

Compatible with modern life

Many people find strong snus to be a very appealing option because of these factors. The rise in popularity is in line with other tobacco trends.

How do you measure the strength of snus?

The amount of nicotine in snus determines how strong it is. This measurement is very important for both users and makers. It helps people pick the right product for their needs.

The amount of nicotine in snus can be very different. There are options that are weak and very strong. Users can choose from this range based on how much nicotine they can handle.

The packaging of snus often tells you how strong the nicotine is. When you measure it in milligrams per gram (mg/g), it makes sense. People use this information to help them decide what to buy.

Important Things:

All of these parts affect how people use snus. Knowing them helps you make smart decisions.

Pros and Cons of Using Strong Snus

There are a number of possible benefits to using strong snus. One of its main benefits is that it helps reduce harm. For people who want to quit smoking, it can be a good option.

Also, snus is very easy to use. People like being able to use nicotine without anyone knowing. Unlike cigarettes, it doesn’t make you spit or make secondhand smoke.

But there are risks that come with strong snus. It still has nicotine, so keep that in mind. There is still a risk of addiction with any nicotine product.

Think about the following:

Users can make smart choices by weighing these pros and cons. It’s important to know what your health priorities are.

Trends in the market and what customers want

The market for strong snus is growing quickly. This growth is being driven by a rise in interest in smokeless products. People want high-nicotine options that don’t have the risks of smoking.

Snus is more appealing because it comes in a range of flavors. There are options for everyone, from mint to fruity. New packaging makes products easier to find and use.

Important Trends Noticed:

-

More and more people are interested in nicotine products that don’t smoke.

-

Different flavors appeal to different groups of people.

-

Better packaging for ease of use

These trends point to a good future for strong snus. The changing market promises more choices. Consumer demand still has an effect on how products are made.

Rules and the Legal Landscape

There are a lot of different rules for snus. Some countries have very strict rules about sales. Others are more lenient and let people in easily.

There is a lot of disagreement about legal classifications. Regulatory frameworks may change as demand grows. It’s important for both consumers and producers to keep an eye on these changes. Knowing the law helps you make smart choices.

The Future of Strong Snus: The End

There is a lot of room for growth in the strong snus market. Demand is likely to go up as more people want high-nicotine alternatives. New flavors and packaging keep bringing in new users.

Some health concerns still exist, but a lot of people see strong snus as a modern alternative to smoking. As the market changes, we might see more people accept it and use it in their daily lives.

It will be important for both consumers and manufacturers to keep an eye on changes to the rules. This will help them find a balance between growth and safety.