What Are the Best Nicotine Pouches?

The market for nicotine pouches has grown quickly because adults want nicotine options that don’t involve tobacco, smoke, or being obvious. Many people, both consumers and distributors, ask the same question: What are the best nicotine pouches? There are so many brands and flavors to choose from.

This article looks at the best pouch options, what makes them unique, and how distributors can find high-quality alternatives to meet the growing demand.

What Makes a Nicotine Pouch the Best?

Not all nicotine pouches are the same. When you look at your options, keep these things in mind:

- Strengths of Nicotine – Strength is important for consumer preference, and it can be as low as 2 to 4 mg or as high as 10 mg or more.

- Different flavors, like mint, citrus, berry, coffee, and even special blends, help brands reach different groups of customers.

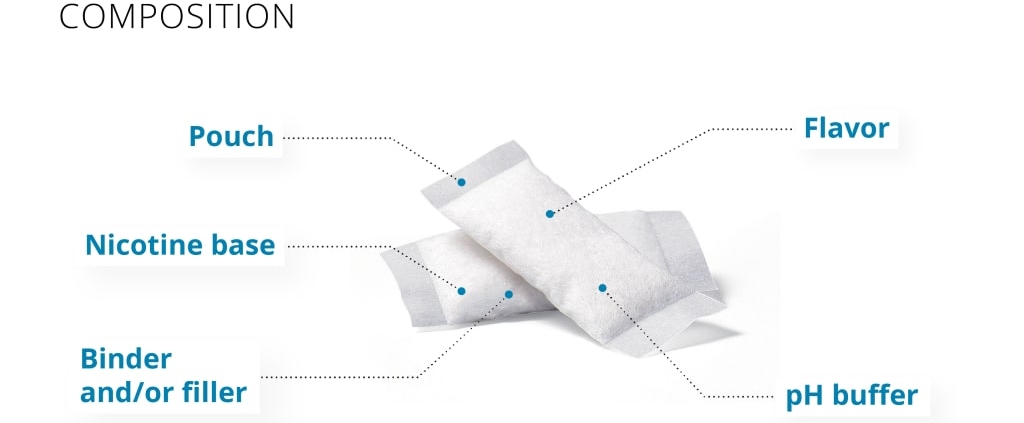

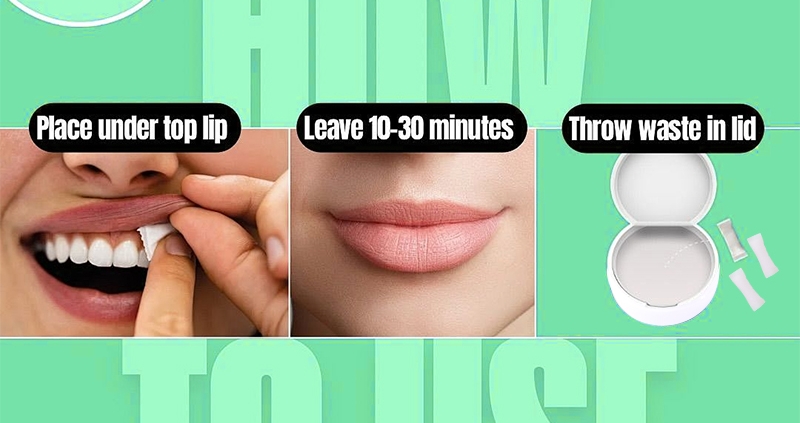

- Comfort and Texture: High-quality pouches use plant fibers to make them fit smoothly and comfortably under the lip.

- Discreet Packaging: Sleek, portable cans are a must for convenience on the go.

- Safety and Compliance: Products made under strict quality controls earn consumers’ trust over time.

Well-Known Brands of Nicotine Pouches

Customers know a lot of brands well:

- Zyn is a well-known brand in the U.S. and Europe that is known for its mint and citrus flavors.

- Velo has a lot of different flavors and nicotine levels to choose from, so everyone can find something they like.

- On!—Small, portable pouches that are great for people who want to use them in private.

- Rogue: Known for strong flavor combinations like coffee and wintergreen.

These brands are very popular in Western markets, but international distributors don’t always have easy access to them because of rules and limited supply.

Options for Global Distributors

Working directly with trustworthy manufacturers gives wholesalers, retailers, and brand owners more freedom than relying on well-known brands. Some of the benefits are:

- A steady supply chain for large orders

- Private-label chances to make your own brand

- Nicotine strengths and flavors that can be changed

- Prices that are competitive in new markets

Echi: Your Reliable Source for Nicotine Strips and Pouches

Echi is a top nicotine supplier in China. We make:

- High-quality nicotine pouches & strips with flavors and strengths you can choose

- Nicotine strips that dissolve quickly for today’s adults

- OEM and private-label services for distributors all over the world

When buyers work with Echi, they get access to high-quality, compliant products and help with global exports, which is a big plus in today’s growing nicotine market.

Final Thoughts

The answer to the question “What are the best nicotine pouches?” depends on who you are trying to sell them to. Zyn, Velo, and On! are still popular with customers. For distributors, the best choice is often to work with a manufacturer like Echi. This way, you can get high-quality products, make changes to your offerings, and ensure a steady supply chain.

Frequently Asked Questions:

1. Which nicotine pouch brands are the most well-known?

In the U.S. and Europe, Zyn, Velo, On!, and Rogue are some of the most well-known brands.

2. Are all nicotine pouches free of tobacco?

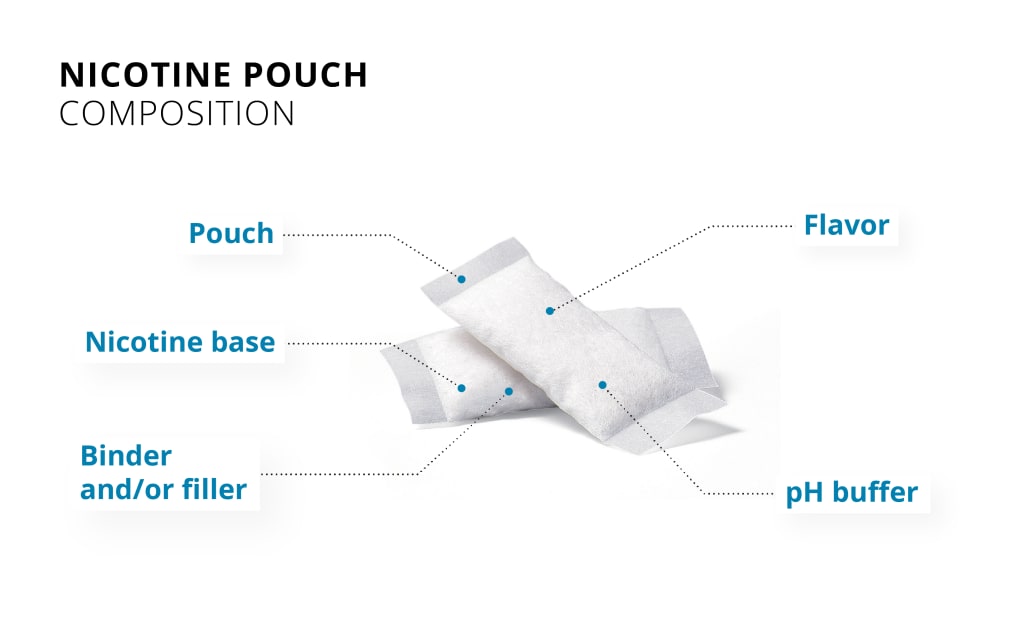

Yes, most modern nicotine pouches don’t have any tobacco in them. They just have nicotine, plant fibers, and flavorings.

3. What level of nicotine should I pick?

People who don’t smoke much usually start with 3–4 mg, while people who do smoke a lot may prefer 8–12 mg pouches. Distributors should have a range of products.

4. Are nicotine pouches better for you than smoking?

Nicotine pouches are thought to be a lower-risk option because they don’t have any smoke, tar, or other harmful chemicals that come from burning.

5. Where can I get nicotine pouches in bulk?

Echi offers high-quality nicotine pouches and strips to global distributors, as well as OEM and wholesale options.