Exploring the Rise of Coffee Dip Bags: Insights from a Leading Nicotine Bag Manufacturer

For centuries, coffee has captivated the senses with its rich aroma and bold flavor, earning a permanent place in global culture. Now, innovation in how coffee is consumed is reshaping the industry. One such innovation is the coffee dip bag—an on-the-go, brew-in-the-bag concept that combines flavor, convenience, and portability. But what exactly goes into creating these sachets? And how can emerging brands tap into this growing trend?

As a nicotine bag manufacturer with a deep understanding of precision production and fast-evolving consumer markets, we offer a unique lens on the coffee dip bag industry—its processes, trends, and what to look for in a reliable supplier.

2. Industry Background and Trends

The global coffee market continues to thrive, but recent years have seen a significant shift: consumers now favor convenience as much as quality. This behavioral change has driven demand for innovative delivery formats, including coffee dip bags.

Comparable in design to tea bags, coffee dip bags offer a single-serving solution that delivers a freshly brewed experience—anytime, anywhere. Their popularity has surged in both developed and emerging markets, driven by:

-

Urban lifestyles and mobile consumption habits

-

Minimal preparation requirements

-

Growing preference for premium, small-batch coffee options

As with the rise of nicotine pouches in the smokeless tobacco sector, coffee dip bags are now becoming a staple in modern, wellness-conscious consumption patterns.

3. Production Process of Coffee Dip Bags

The journey of a coffee dip bag begins with high-grade beans sourced from reputable regions—often Arabica or Robusta variants from Ethiopia, Colombia, or Vietnam. These beans are then:

-

Roasted to precise profiles under expert supervision to ensure optimal flavor balance.

-

Ground into uniform granules to support fast, full-bodied extraction.

-

Filled into heat-resistant, food-safe mesh pouches, which are engineered to allow water to infuse flavors while retaining the grounds.

-

Vacuum-sealed to lock in freshness, aroma, and shelf stability.

Large-scale production demands stringent control and modern machinery—much like the processes involved in nicotine bag manufacturing. Precision, consistency, and hygiene standards are critical across both industries to ensure product integrity.

4. Differences in Brands, Origins, Equipment, and Technology

Not all coffee dip bags are created equal. Distinctions arise across several key factors:

-

Bean origin and quality: Single-origin beans often yield more distinctive flavors than commercial blends.

-

Roasting techniques: Artisanal slow roasting offers deeper profiles compared to high-speed industrial methods.

-

Grinding consistency: Uniform granule size is vital for controlled extraction.

-

Packaging and pouch technology: Advanced filter mesh ensures a clean brew while enhancing aroma dispersion.

These factors closely mirror distinctions in the nicotine bag industry—where raw material origin, pouch permeability, and manufacturing technology determine user experience and product value.

Brands that invest in premium equipment and uphold rigorous quality control stand out in both sectors, delivering consistency and reliability batch after batch.

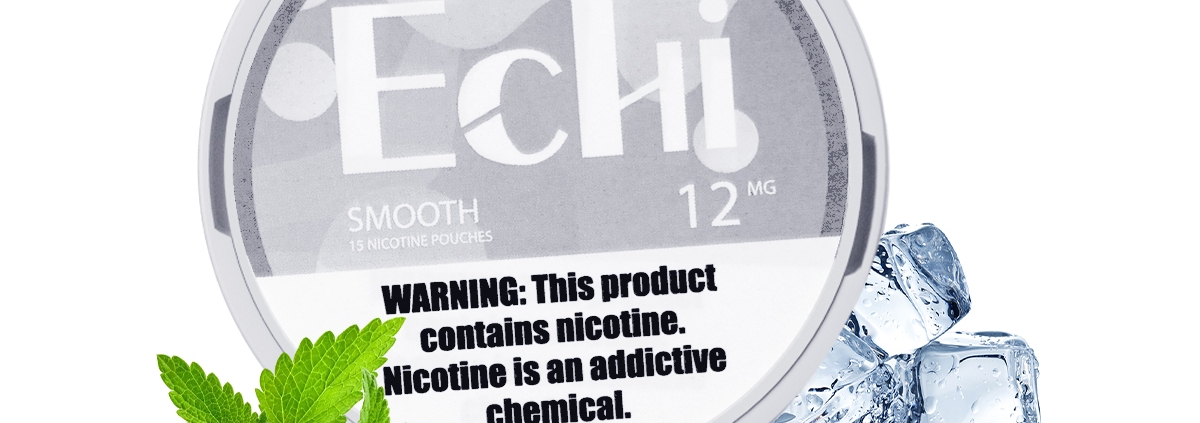

5. Choosing a Reliable Supplier – Echi Nicotine Bag Manufacturer

At Echi, we’ve built our reputation on delivering dependable nicotine pouch solutions to global white-label clients. That same expertise applies to fast-moving sectors like coffee dip bags.

What sets Echi apart as a supplier?

-

Production Excellence: Our nicotine bag facilities employ advanced machinery and QC protocols—ideal for cross-application to food-safe pouch manufacturing.

-

OEM & White-Label Expertise: We empower our partners with full customization—from flavor formulation to packaging—mirroring the brand-building process in coffee products.

-

Transparent Collaboration: We operate with openness, consistency, and a solutions-first mindset, enabling long-term, scalable partnerships.

When choosing a coffee dip bag manufacturer, look for the same criteria we champion in nicotine production: proven track record, production flexibility, compliance, and a partner-like approach. Learn more about our white-label capabilities here: white label nicotine bag

6. Final Suggestions for New Entrants and Brand Builders

If you’re exploring entry into the coffee dip bag market, consider these recommendations:

-

Partner with manufacturers who understand pouch-based production, particularly those with experience in adjacent industries like nicotine or herbal alternatives.

-

Prioritize suppliers who offer customization, allowing your product to stand out through unique blends, formats, or packaging.

-

Start small, but plan to scale. Seek suppliers with low minimum order quantities (MOQs) but scalable capacity—just as we offer through Echi.

Remember: the right supplier is not just a vendor but a strategic partner in your brand’s growth. Get in touch for B2B collaboration: nicotine manufacturing

7. Conclusion

Coffee dip bags represent a compelling fusion of convenience, craftsmanship, and evolving consumer habits. Their growth trajectory mirrors that of nicotine pouches—offering a case study in how niche products can go mainstream with the right combination of innovation and quality.

At Echi, our understanding of pouch-based manufacturing and white-label development equips us—and you—for success in this space. Whether you’re launching a new product or expanding your portfolio, the coffee dip bag industry holds enormous potential, and choosing the right manufacturing partner will be your first step toward market leadership. Explore manufacturing solutions inspired by nicotine industry best practices at nicotine bag manufacturer

Anchor Links for Reference

Leave a Reply

Want to join the discussion?Feel free to contribute!